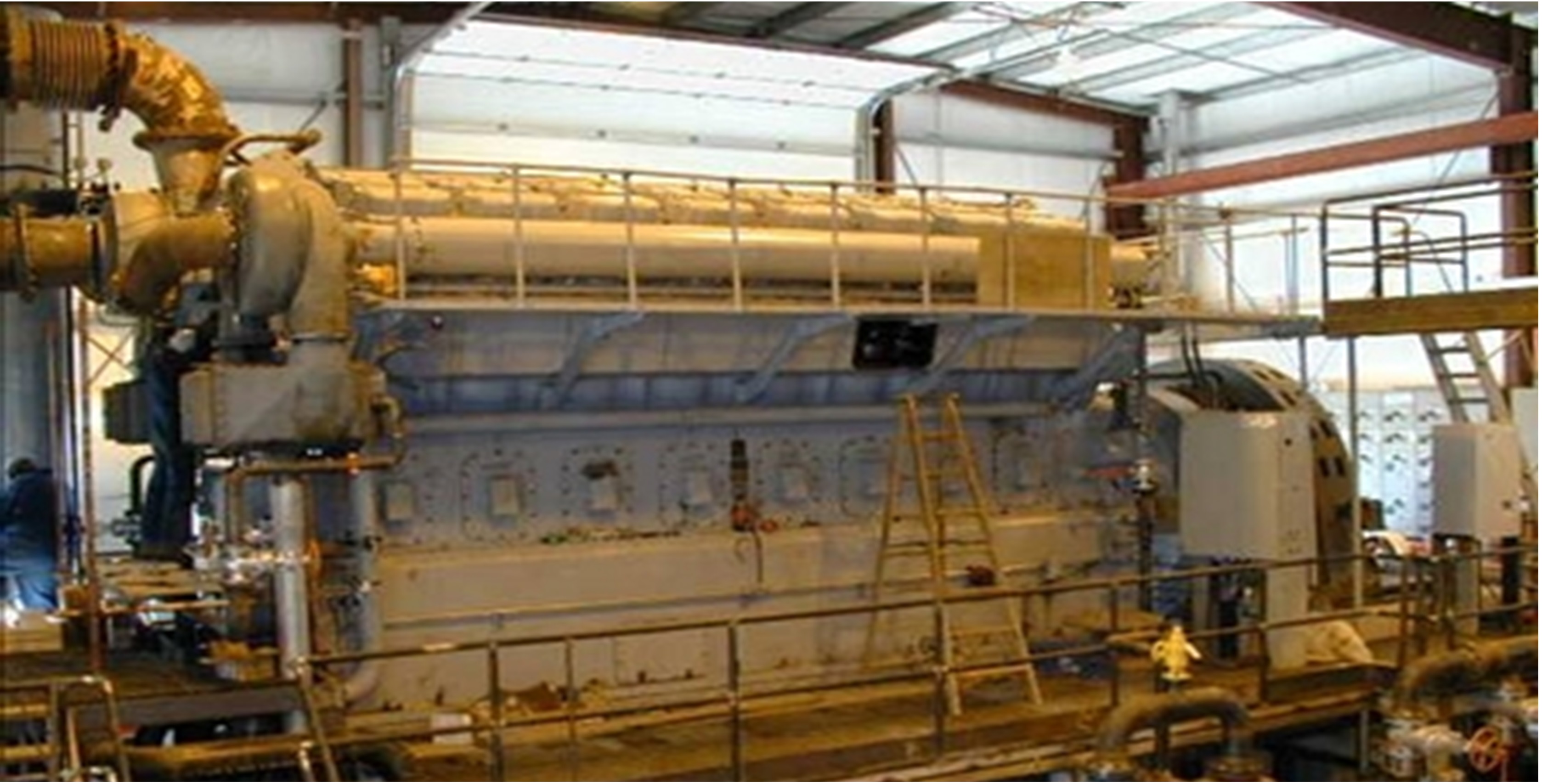

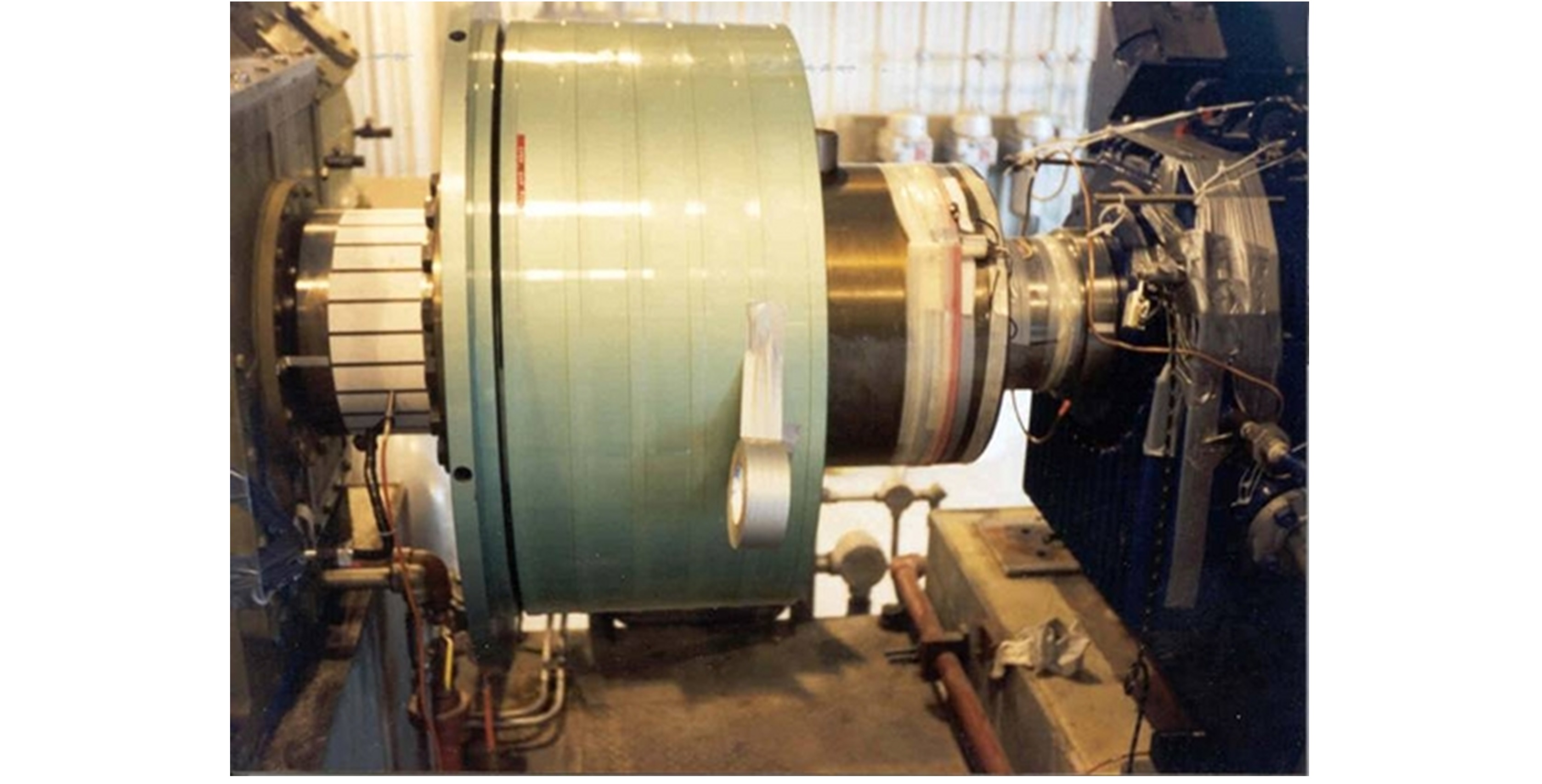

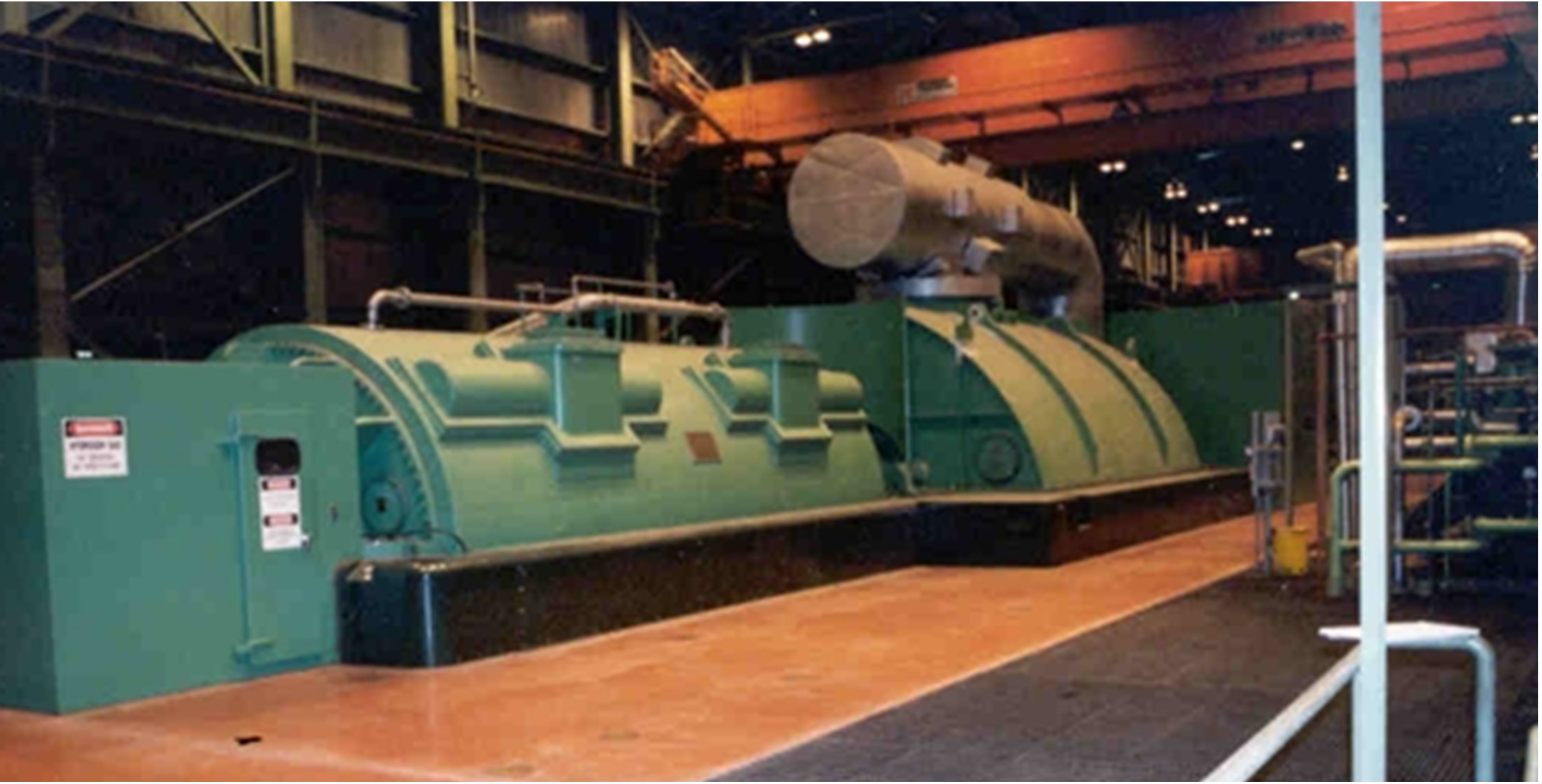

RBTS provides both field and analytical rotating machinery dynamics engineering services for shipboard equipment. For this type of application, RBTS has provided field measurements and analytical services to understand and solve a wide variety of torsional and later rotordynamic problems.